CEDRAT- Actuators & motors based on piezoelectric ceramics

In order to meet varying customer actuation specifications, CEDRAT has developped different families of standard piezoelectric actuators with their corresponding drivers and controllers:

- ● Parallel Pre-stressed Actuators (PPA)

- ● Amplified Piezoelectric Actuators (APA®)

- ● Piezo Stages

- ● Fast Steering Mirrors

- ● Fast Piezo Shutters

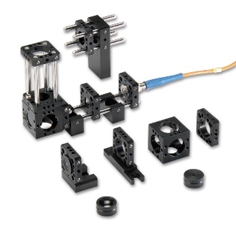

EXCELITAS-LINOS- Precision Optomechanic Products

We offer a variety of precision optomechanic products,including: Microbench and Nanobench Cage Systems, Mirror Mounts, Posts, Holders, and Positioners, as well as Enclosed Tube-C, Rail and heavy-duty X-95 Profile systems.

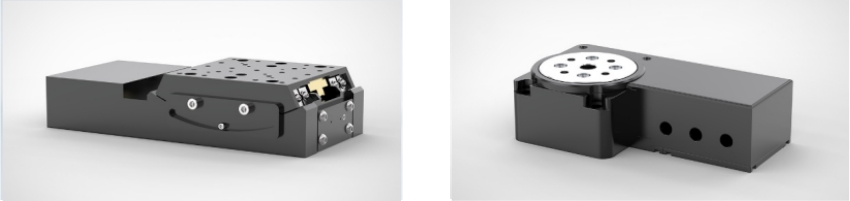

Feinixs' product line mainly includes motion control products,Including linear motion stage, rotational motion stages, and vertical motion stages, and also include driver work with these stages.

- • Motorized Linear Motion Stage

The Motorized Linear Motion Stages covers a wide range of precision linear positioning stages, Used to achieve precise motion.

- • Motorized Rotational Motion Stage

Motorized Rotational Motion Stage is used for precise control of rotation angle and speed, and for precise positioning, testing, measurement, and machining work.

- • Motorized Linear Vertical Motion Stages

Motorized Linear Vertical Motion Stages provides Z-axis displacement for 3D scanning, and its compact design allows it to be applied in scenarios where space is limited.

- • Motion Control Systems

We provide multi-axis motion control systems and guarrante system accuracy. In addition to our standard version, we also offer stainless steel and vacuum version.

- • Motion Control Driver

Our driver can work with servomotor, piezoelectric motor and step motor.

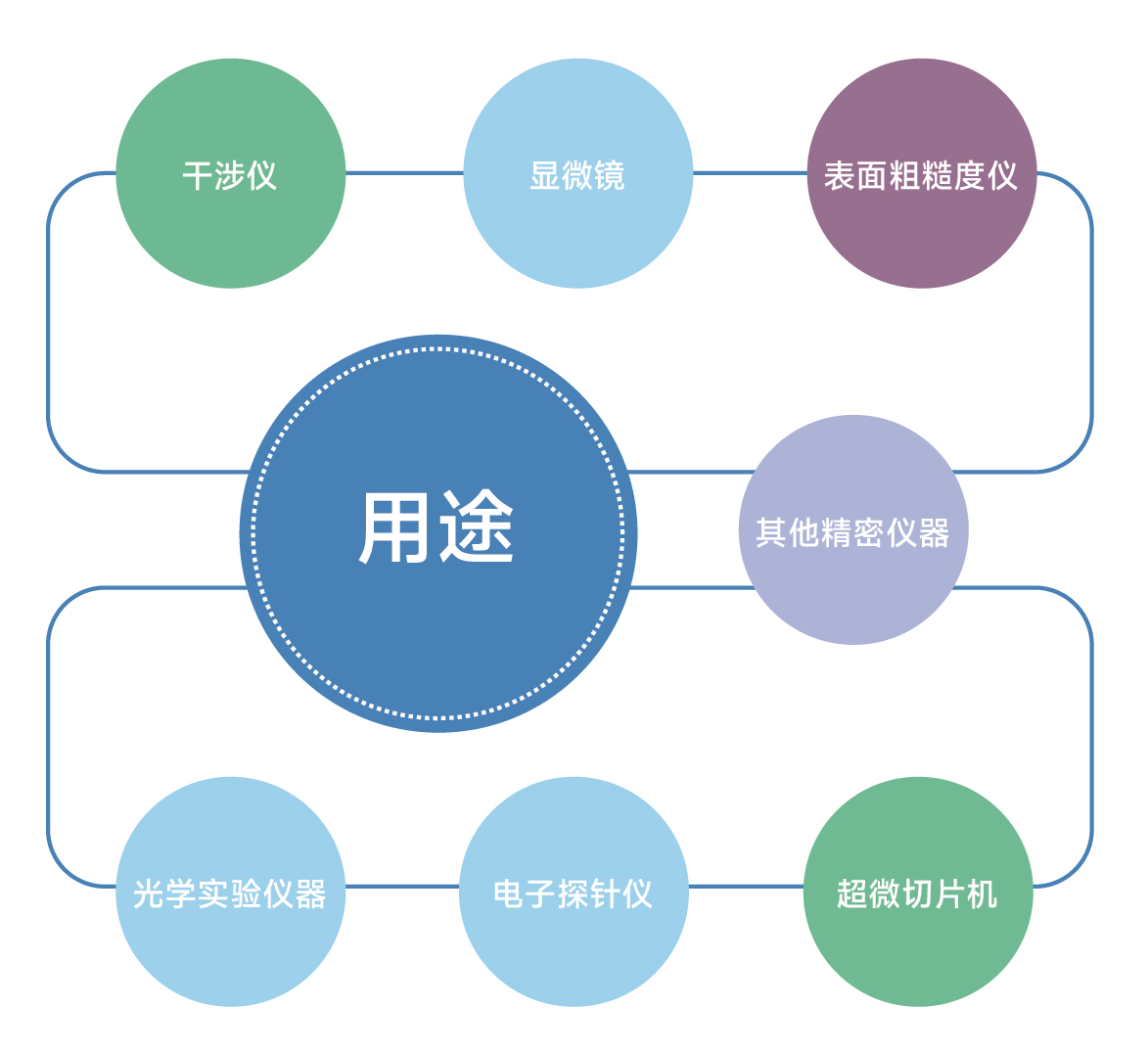

Meiritsu accumulated know-how and expertise have produced more than 600 types of passive vibration isolators, to date. There is also growing demand for our active vibration isolators, particularly in the ultra-high precision manufacturing industry, such as semiconductors.

Surface Vibration Table

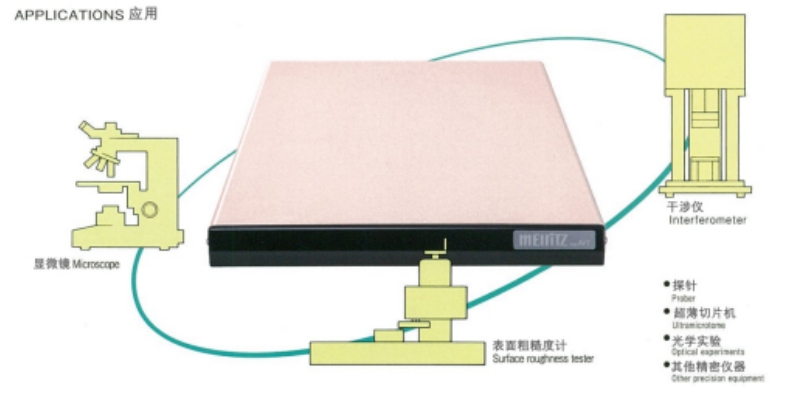

- • AYA Series- Honeycomb table air suspension vibration isolator

The AYA Series is Meiritz's top-of the line series which features improved isolation performance and various useful functions. The AYA Series is the crystallization of advanced technology developed entirely by Meiritz. In particular, through improvement of holizontal direction vibration isolation performance, the AYA Series is able to respond to the optical experimentation needs including interferometers and holography equipment which are sensitive to minute vibrations in all directions.

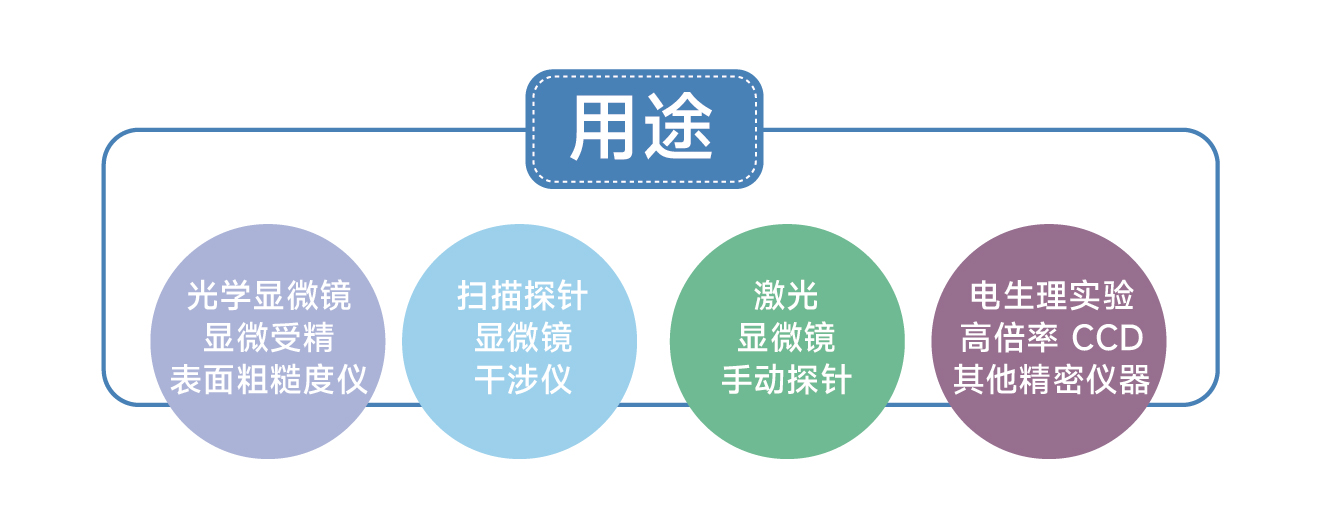

Applicaiton:

• Optical & Laser Experiments

Desk type Vibration Table

- • Desk type air suspension vibration isolator

High cost performance, vibration isolation performance.

The ADZ-A series is a highly upgraded version of the well-selling ADZ series. Vibration isolation performance is further enhanced, working comfort is greatly improved, and a model with a larger mounting plate has been added to the new series. Also, a wealth of options is available for better operability of the equipment installed on the isolator. This high cost performance vibration isolator can accommodate a wide range of equipment and can be used almost anywhere.

Applications:

Tabletop Vibration Table

- • AVT series-Desktop air suspension vibration isolator

There are desktop vibration absorption boards featuring advanced air suspension type vibration isolators. All vibration isolation functions are incorporated in a compactly designed body. Sixteen models, diversified in characteristic, are available. The designs are sophisticated considering operation conditions sufficiently. The high-performance AVT Series, incorporating stage-of the-art technology, will fulfill all your needs. We are confident in recommending the AVT Series for small-medium-scale precision machines and those for machining minute parts. The AVT Series assures their maximum potentials by isolating them from vibration.

Applications:

- • ME Series- Desktop type Active Vibration Isolation System

Desktop type Active Vibration Isolation System in three dimensions (six degrees of freedom) The system can control vibration in three dimensions (six degrees of freedom) while continuously monitoring the vibration of the lading table. This is done by using an integrated actuator to provide an opposite phase signal to the measured vibration.

- • AET series- Desktop steel honeycomb air suspension vibration isolator

The AET Series is a series of desktop vibration isolators that bring together an entire high-performance vibration isolation system. At Meiritsu Seiki, many of our previous desktop vibration isolators have been combined into a series. As a result, the AET Series, which combines these vibration isolators with steel honeycomb surfaces tables, consists of desktop air suspension vibration isolators are optimal for optical experiments using a small surface area.

Applications:

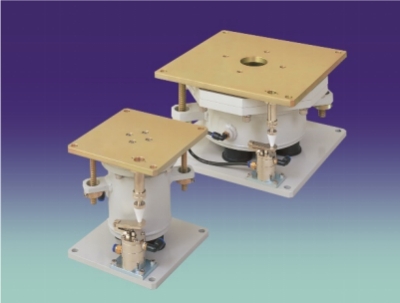

Unit type Isolator

- • MAPS series-Active Pneumatic Suspention System MAPS

Six degree of freedom active control provides excellent vibration isolation, damping and positioning performance for all degrees of freedom vibration MAPS series is an active vibration isolation device, which combines all necessary functions into a compact unit, so it can be easily integrated into the customer's equipment.

Business Fields:

• For Semiconductor

- • MRZ series- Active Pneumatic Suspention System

Based on MAPS series, we have developed high performance and reasonable Active Pneumatic Suspention System MRZ series!

Business Fields:

• For Measurement

• For Semiconductor

Applications:

• FPD,Semicondoctor equipment,Electron microscopy,UHV-SPM,Measuring machine,Ultraprecision machine,etc.

- • AP series-Pneumatic vibration isolation system

You can compose the most suitable vibration isolation system fitted to your precise machines at low cost.

It is important that vibration isolation system has flexibility as well as excellent performance. Because it is the best way to install vibration isolation system that is tuned in on these precise machines. That is "AP Series" vibration isolation system that can be immediately adapted to your needs. In addition to the capacity for vibration isolation, "AP Series" has system extensibility too. This vibration isolation system, "AP Series" materializes an ideal vibration isolation environment.

Business Fields:

• For Measurement

• For Semiconductor

Applications:

Meiritsu's vibration isolation products are widely used in the following fields::

- • Microscope

- • Optical & Laser

- • Measurement

- • Semiconductor

- • Nano Surface Analysis

- • Disaster Control

High tech SME involving more than 70 employees based in the French Innovation Valley, close to Grenoble.

For an harmonious development, CTEC is encouraging the application of its values 3C® Concert, Collaboration & Cordiality, both between its employees and with its partners.

CTEC is specialized in the following domains:

- ● Smart Actuators : Actuators & motors based on piezoelectric ceramics, electroactive polymers, ultrasonic effects, magnetostrictive alloys, magnetorheological fluids (MRF) & magnetic effects (moving coils, moving iron …) ; Applications : micro nano positioning, damping, vibration generation, acoustic transducers, micro actuators …

- ● Smart Sensors : Magnetic, magnetoresistive, magnetostrictive, piezoelectric sensors, transformers or generators ; Force, Torque, Position, Speed, Acceleration sensors, including contactless sensors & resonant sensors.

- ● Mechatronic systems : Multi-degree-of-freedom mechanisms (XY stages, tilts); motion control ; Active damping of Vibrations ; Vibration (Ultrasonic or sonic) assistance to process ; Proportional valves ; Fast injectors

- ● Detection systems : Health monitoring ; NDT using magnetic or acoustic effects ; Remote detection systems for position, force, torque remote measurements.

- ● Technological training courses: CEDRAT TECHNOLOGIES provides comprehensive training courses dedicated to engineers and technicians who wish to discover, improve or recover their knowledge in mechatronic products, systems and technologies.

Backed by years of experience, CEDRAT TECHNOLOGIES’s extensive R&D activity is conducted by a multidisciplinary team of experts. Its laboratories are equipped with a complete library of engineering software and specialised measurement apparatus.

Between the standard products and the customised solutions, CEDRAT TECHNOLOGIES provides existing “building blocks” to move quicker from specifications to a complete optimised design and evaluated prototypes.

Widely applied for precise and rapid actuation, optics, instrumentation and control of vibrations, mechatronic products based on smart materials meet the most stringent specifications for aerospace and industry.

LINOS® Optomechanics from Excelitas feature high-precision engineering and highest-grade materials to ensure premium stability, adjustablility and performance in your scientific research and photonic innovation. We offer a variety of precision optomechanic products from our rich Qioptiq® heritage including: Microbench and Nanobench Cage Systems, Mirror Mounts, Posts, Holders, and Positioners, as well as Enclosed Tube-C, Rail and heavy-duty X-95 Profile systems.

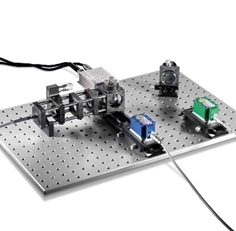

LINOS Breadboards & Mounting Plates

Excelitas' line of LINOS® Breadboards and Mounting Plates are the perfect starting point for any experimental optical setup.

LINOS Diaphragms

Springing from our Qioptiq® lineage, Excelitas offers a wide range of precision LINOS® Iris Diaphragm, Pinhole and slit consticture for exacting light control in your experimental setups.

LINOS Microbench Optomechanic Cage System

The original Optomechanical Cage System, Microbench is compact, precisely centered, simple to integrate and expand. With an expansive range of optical and mechanical components, LINOS® Microbench is an integral part of many optomechanical set ups. Optimized for use with optics from 18-31.5 mm Ø.

LINOS Mirror Mounts

Mirror mounts are an essential element in optical assemblies. The variety of mounts available from Excelitas includes Lees, LINOS® Standard and LINOS Adjust.X Mirror Mounts to meet a range of requirements across science and industry.

LINOS Mounts & Posts

Excelitas' comprehensive range of LINOS® Mounts, Posts and Holders includes object holders for rectangular and cylindrical elements, as well as for mounted and unmounted optics or prisms.

LINOS Nanobench

LINOS® Nanobench System is a precision construction system for beam diameters up to ½" with a more compact footprint than that of our LINOS Microbench System.

LINOS Positioners

Excelitas offers a broad range of precision LINOS® Positioners including manual positioners, linear positioners, X-Y stages, rotary stages and goniometers with assorted adjustment ranges and load capacities.

LINOS Rail Systems

LINOS® Rail Systems enable the construction of optical benches and beam steering systems. The bearing surfaces on the sturdy aluminum alloy are precision-milled and treated with abrasion-resistant black or colorless anodizing, making these rail systems an ideal basis for linear, areal and even 3-dimensional structures.

LINOS Tube System

The perfect compliment to our LINOS® Microbench and Nanobench open cage optomechanical systems, Excelitas also offers the enclosed, modular LINOS Tube System for applications demanding light-tight, dust-free experimental set ups.